Additive Manufacturing (3D Printing)

Why use additive manufacturing?

Reduce manufacturing and machining costs

Reduce clutter: keep a repository of parts digitally, not physically

Easily send electronic files instead of a physical part for remote jobs

Improve supply chain efficiency

Easily 3D print complex geometries

Eliminate tooling spend

Safe, automated processes

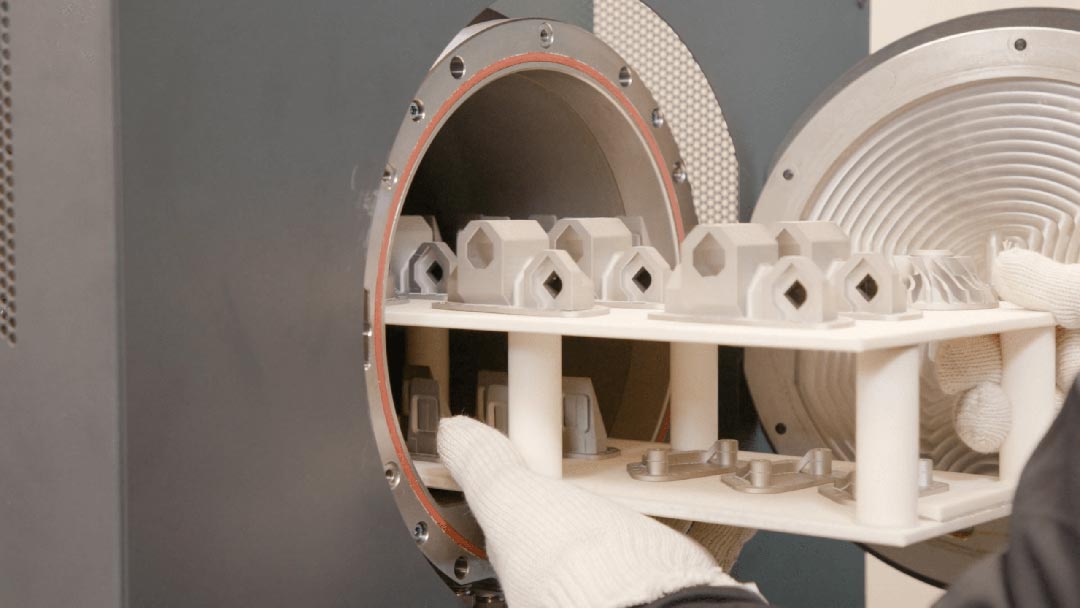

Metal X

Starting at $200,000

Everything you need to go from design to fully functional metal parts in under 24 hours! The Metal X 3D print system is an end-to-end manufacturing solution. The Metal X is up to 10x less expensive than alternative metal additive manufacturing technologies and up to a 100x less than traditional fabrication technologies like machining or casting. The cloud-based printer management software, built-in touchscreen interface and automatic material tracking make the Metal X system the simplest way to manufacture metal parts.

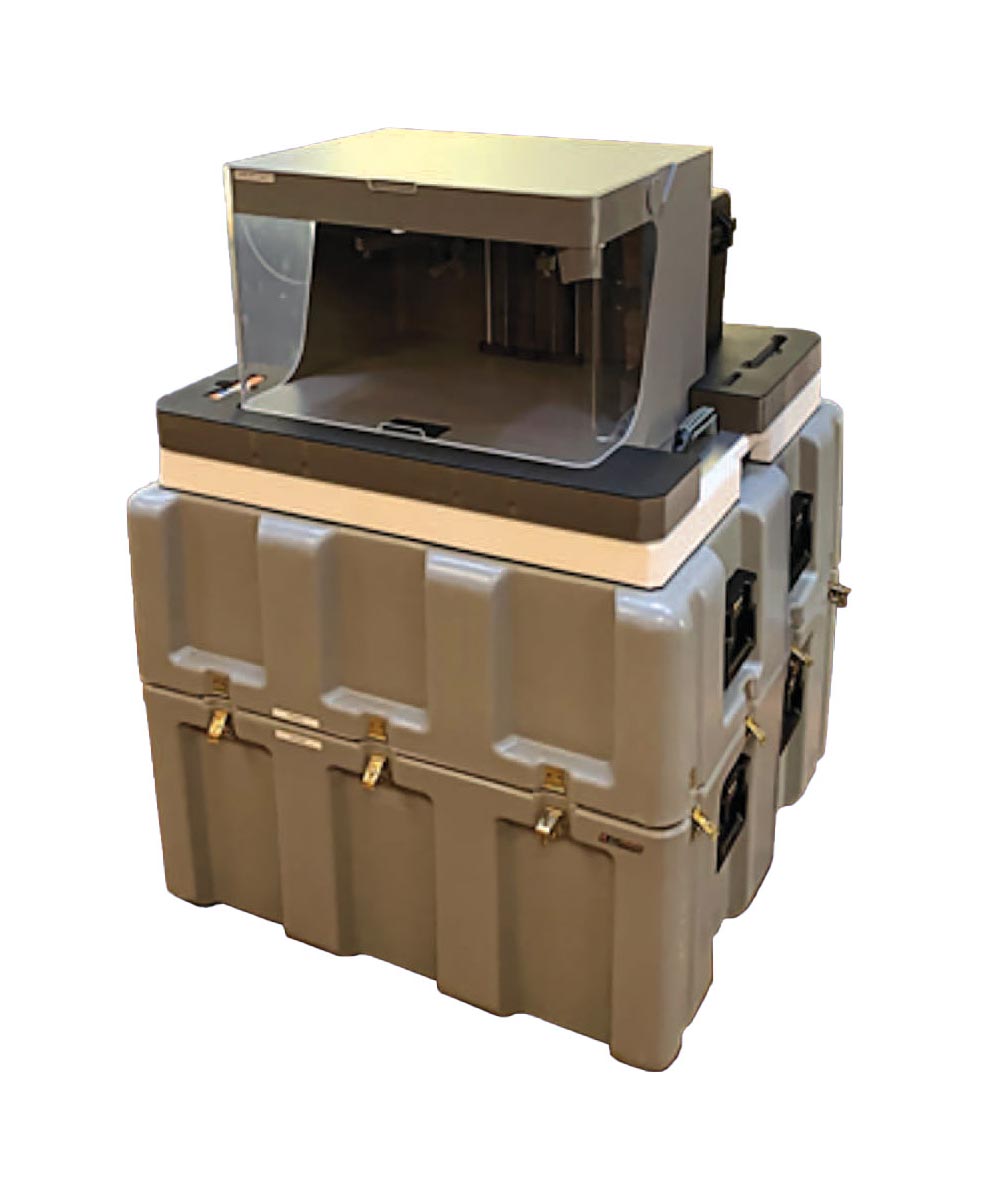

Field Edition X7

The Field Edition X7 combines the full capability of the Markforged X7 printer, with a rugged case and accessories. Print continuous carbon fiber composite parts that are stronger than 6061 Aluminum, and 40% lighter. The Field Edition comes with all the materials, replacement parts, and tools needed for months of deployment in the harshest environments. Go from fully packaged to printing in under 3 minutes.

Industrial Composite X7

Built from the ground up for reliable performance, the X7 delivers breakthrough quality and precision in 3D printing. The top-of-the-line industrial grade platform features a strengthened dual nozzle print system that supports Continuous Carbon Fiber and Kevlar reinforcement. Laser inspection scans parts mid-print to ensure dimensional accuracy for the most critical tolerances.

Metal 3D Printing Materials

17-4 PH Stainless Steel

Combines high strength, corrosion resistance, and hardness. Used in a wide variety of manufacturing applications.

D2 Tool Steel

Can be air-hardened to 60 HRC; trades toughness for hardness and abrasion resistance. Great for cutting tools and dies.

316L Stainless Steel (In Development)

Exhibits excellent corrosion resistance. Used in marine applications.

H13 Tool Steel

A hot-work tool steel with excellent toughness, wear resistance, and heat resistance. Excels in high temperatures.

Inconel 625

A proprietary nickel alloy that excels in high temperatures and corrosive environments. Used in automotive and aerospace.

Titanium Ti6Al4V (In Development)

Superior strength-to-weight ratio. Used in aerospace, medical, and other high-performance fields.

A2 Tool Steel

Can be air-hardened up to 58 HRC; excellent impact resistance. Used for forming tooling, punches, and dies.

Copper

Thermal and electrical conductivity. Print heat sinks, custom conductive elements, and other geometrically complex parts.

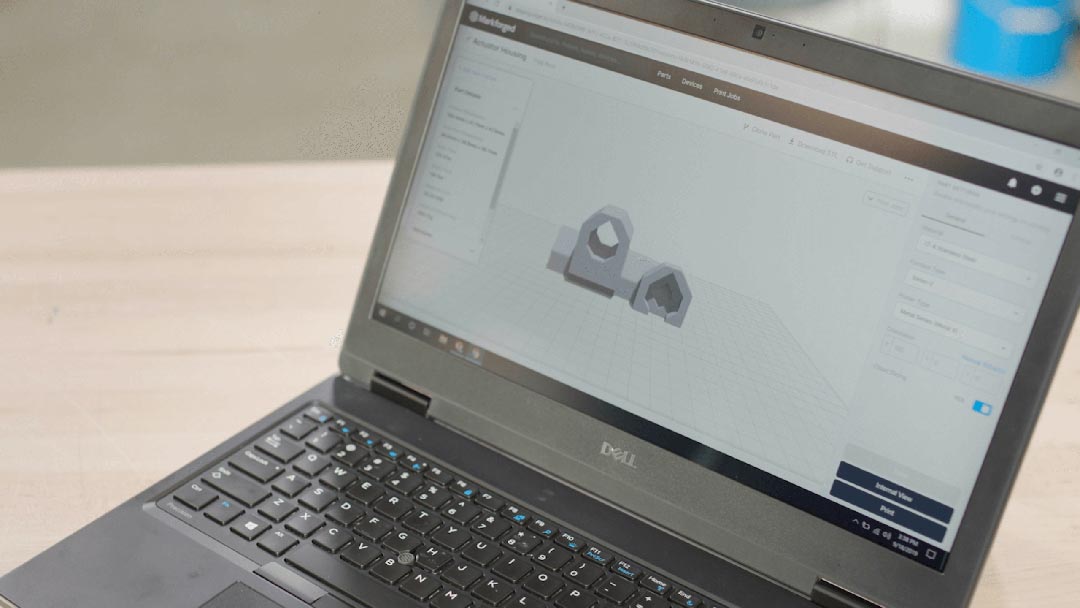

Markforged Metal 3D Printing Process

Design & Slice

Wash